Strain Gauges

Strain Gauges: Precision Measurement for Stress and Strain Analysis

Definition of Strain Gauges

Strain gauges are specialized sensors designed to measure the strain (deformation) of an object under applied force or load. By detecting minute changes in electrical resistance when the gauge is stretched or compressed, strain gauges provide critical data for stress analysis, structural integrity testing, and load monitoring. They are widely used in industries where precise mechanical measurements are essential, such as aerospace, automotive, civil engineering, and manufacturing.

Types of Strain Gauges

- Foil Strain Gauges: The most common type, featuring a thin metallic foil pattern on a flexible substrate. Ideal for general-purpose stress analysis due to their high sensitivity and durability.

- Wire Strain Gauges: Utilize fine wire elements for high-temperature or rugged environments. Often used in heavy industrial applications.

- Semiconductor Strain Gauges: Made from silicon or germanium, offering exceptional sensitivity but higher temperature sensitivity. Suitable for precision electronics and miniaturized systems.

- Piezoresistive Strain Gauges: Leverage the piezoresistive effect in materials like silicon for ultra-high sensitivity, commonly used in MEMS (Micro-Electro-Mechanical Systems).

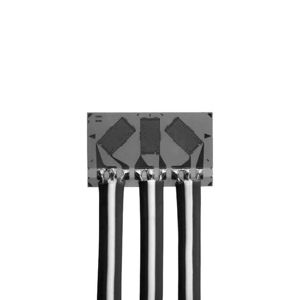

- Rosette Strain Gauges: Configured in multiple directions (e.g., 45 or 120 rosettes) to measure complex multi-axis strain fields.

Buying Recommendations for Strain Gauges

- Application Compatibility: Select a gauge type (foil, wire, semiconductor) based on environmental conditions (temperature, humidity) and required precision.

- Material & Adhesive: Ensure the gauge material (e.g., constantan, nickel-chromium) and adhesive (epoxy, cyanoacrylate) match the substrate (metal, plastic, composite).

- Resistance & Sensitivity: Standard gauges typically range from 120 to 1k ; higher resistance reduces current flow and self-heating.

- Certifications: For critical industries (aerospace, medical), prioritize gauges with ISO 9001 or ASTM E2514 compliance.

- Supplier Expertise: Partner with manufacturers offering technical support for installation, calibration, and signal conditioning (e.g., Wheatstone bridge integration).

Strain gauges are indispensable for ensuring safety, efficiency, and reliability in structural and mechanical systems. Investing in the right type and configuration will optimize accuracy and longevity for your specific use case.

Filter and sort

Categories

MMF404896

C4A-03-235SL-120-39P - STRAIN GA

MMF404286

C4A-06-235SL-350-33P - STRAIN GA

MMF404031

C4A-13-060SL-350-39P - STRAIN GA

MMF404542

STRAIN GAUGE 350 OHM RECT

FS-L-095-103-ST

FLEX SENSOR 10K OHM 112.24MM

MMF404889

C4A-03-235SL-350-39P - STRAIN GA

MMF404776

C4A-06-125SL-350-315P - STRAIN G

MMF404823

C4A-13-125SL-350-29P - STRAIN GA

MMF323482

C2A-06-G1350-120/SP70 STACKED RO

MMF404864

STRAIN GAUGE 350OHM LINEAR

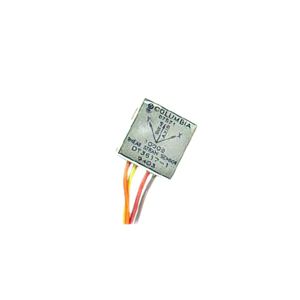

DT 3617-3

STRAIN SENSOR/SHEAR STRAIN MEASU

DT 3625-2

STRAIN SENSOR/MINATURE SIZE

MMF402184

C5K-06-S5145-350-39F

MMF403735

C5K-13-S5145-350-39F

MMF404150

C4A-06-125SL-120-29P - STRAIN GA

MMF404152

C4A-06-060SL-350-29P - STRAIN GA

MMF307425

C2A-13-125LT-350 STRAIN GAGES (1

MMF404888

C4A-03-125PR-350-39P - STRAIN GA

MMF404775

C4A-06-060SL-120-23P - STRAIN GA

MMF403206

C5K-13-S5145-350-33F